The Evolution of Prosthetic Materials

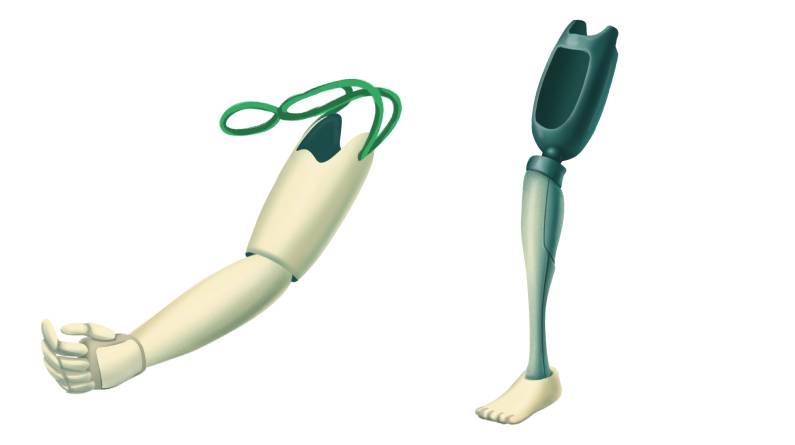

Advances in technology and medicine have led to the development of prosthetic devices that can replace many body parts, improving the quality of life for amputees. Prosthetics are a key part of bio-mechatronics, a field that combines mechanical devices with human muscle, skeletal, and nervous systems.

Key Features of Prosthetic Materials

When selecting materials for prosthetic devices, several factors are considered, including:

– Compressive strength

– Torsional strength (resistance to twisting and turning)

– Tensile strength (resistance to pulling apart)

– Shear strength (impact force)

– Specific density

– Energy storage characteristics

– Stiffness

– Shock absorption

– Fracture resistance and fatigue resistance

– Biocompatibility (non-allergic)

Materials Used in Prosthetics

A variety of natural and synthetic materials are used in creating prosthetics, including:

– Metals: Aluminum, titanium, magnesium, copper, steel, and others are used as pure metals, alloys, or in mixed states. Titanium is a popular choice due to its strength, lightweight, corrosion resistance, and low density.

– Polymers: Softer materials like polyoxymethylene (POM), polyurethane (PU), poly vinyl chloride (PVC), and polyethylene are used in phalanges, joints, and other smaller body parts.

– Carbon Fibers: Known for their high stiffness, high tensile strength, low weight, and high chemical resistance, carbon fibers are often used in prosthetic devices.

– Supporting Materials: Materials like nylon-reinforced silicone, Spenco, and Poron are used to make prosthetic devices more comfortable and durable.

The Importance of Biocompatibility

Prosthetic devices must be made from materials that are biocompatible, meaning they won’t harm living tissue or skin. This is crucial, as prosthetic devices are subject to constant movement and can rub against the skin, causing tissue breakdown, skin blisters, cysts, or ulcers.

References

https://scholarworks.calstate.edu/downloads/h128ng975